Welding Defects – Do you know that no matter how you try to keep things in order, in the end, a mistake will still happen? For example when you casually drive to your campus or workplace, no matter how often you check your car’s condition, on one of those days your car will experience a malfunction.

Either your tire blew out or transmission malfunctioned or even external disturbances like crashes and getting a ticket from patrolling police officer. It seems like there’s a force of nature that intervenes to turn things into disorder or chaos. If you think so, know that you’re not wrong.

This nature’s behavior is called entropy, a behavior that requires us to put extra effort to negate the tendency of things from their disordered state and keep it in order. That’s why you have to regularly check your car and bring that extra tire everywhere you go.

The same force of nature also applies to weld. As a welder, you really want to weld a sound weld. A sound weld means that there’s uniformity (with very little variation tolerance) everywhere you see, either on the weld surface or on the sub-surface.

A sound weld is the best form of the weld, it will have the ability to withstand its designed stress, which means that the quality of fusion between the weld metal and the parent metal is top-notch. However, entropy also plays a role to spread chaos in welding. If the welder is unaware and somehow makes a mistake, it will result in non-uniform weld metal.

Now, this non-uniform phenomenon is what we call discontinuity. So what’s discontinuity and how to avert the forming of discontinuities during welding? This article will give you a clear definition of discontinuity itself that will surely help you as a welder.

Table of Contents :

What are Welding Defects?

Now we know that the existence of discontinuity means that the weldment is not sound. Basically, there are two main categories of discontinuity based on its inflicted damage on the material.

- Reparable Discontinuity.

As the name implies, discontinuity under this category is considered harmless to the material a simple repair action would solve the problem. Most of the mechanical damage such as; scratches, dents, and even surface corrosion falls under this category with the exception of a huge dent because you somehow find a way to drop a huge concrete block on it. While welding discontinuities such as; porosity, slag inclusion, and undercut can either be called discontinuity or defects.

Even when this type of discontinuity is highly tolerated. It is wise for you to always avoid it to train your mind to give your best when doing something. So when the time comes for you to handle a job with stricter regulation on discontinuity, you’ll be ready. - Irreparable Discontinuity.

In some cases, a discontinuity can greatly affect the performance of the weld. Discontinuities like lack of fusion, laminar tearing, and most forms of cracks are one of them. No matter how hard you try to repair it, you’ll only waste your time and resources, making it not worth the fuss. So it’s best for you to avoid it from the very first place by following the correct welding procedure.

How to Deal With Discontinuities?

Because there are just so many forms of discontinuity, there are also many ways to treat them. To make things simpler, let’s talk about them one by one.

10 Welding Defects and Remedies :

This is an explanation of types of welding defects, pictures, causes, and Remedies.

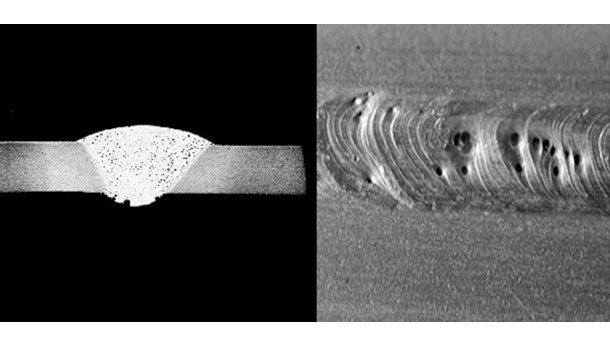

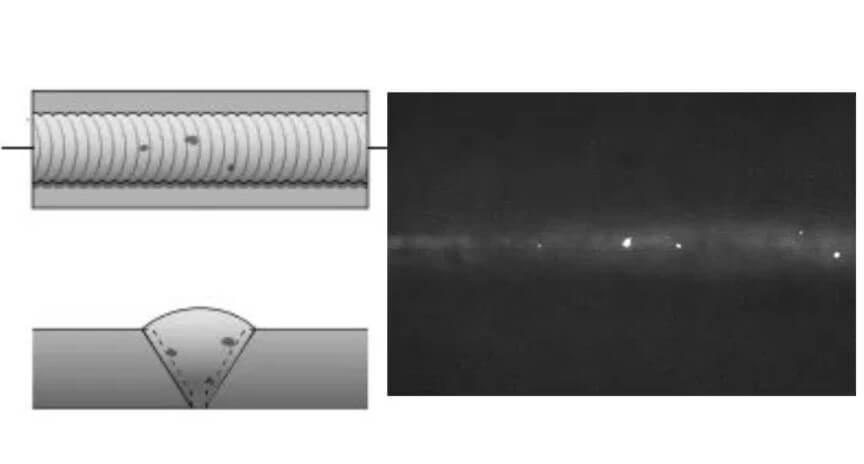

1. Porosity.

Porosity is one of the classic discontinuities that happens in welding. It happens when there are just so many gas molecules trapped inside during welding. Those gasses might come from a wet electrode because the water molecules on the electrode will dissolve due to the heat of welding and result in trapped oxygen that never comes out until the weld pool turns solid.

A windy environment can also promote porosity because the wind will disrupt the shielding environment around the welding arc and allow gasses to enter the molten metal. This porosity can easily be avoided by avoiding contact with the wet environment during welding and making sure that the weld pool is properly shielded with either flux, gas shielding, or both. Several examination methods can detect porosity such as; visual examination, liquid penetrant, radiography examination, etc.

Causes :

- Air trapped in the shielding gas.

- The flux in the electrode is damp.

- Distance arc welding is too long.

- In the welding process which uses shielding gas, the flow rate is too high which can make turbulence.

Prevention :

- Use the electrode in good condition (dry) or the box of the electrode is not broken.

- Clean the surface of the material from oil and another impurity.

- You must reduce the arc length suitable for the welding procedure.

- Use a gas flow rate suitable for welding procedure specification.

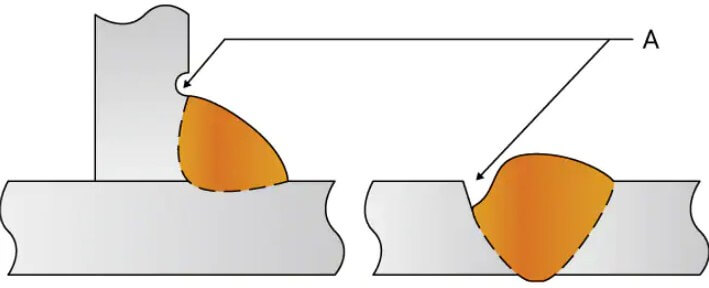

2. Slag Inclusion.

Slag inclusion is also one of the classic discontinuities that occur in welding. It’s a situation when the slag – a protective layer that is supposed to resurface and protect the molten weld pool – is trapped under the geometry of the weld itself.

The trapped slag replaces the supposed filler weld metal with a chunk of Manganese Oxide (may vary) that when you chipped it off will leave the hole gaped, making it good for nothing. The various thing that can cause slag inclusion, dirty weld surface, and a relatively low welding parameter being used is supposed to be the primary cause. Detectable visually, but sub-surface slag inclusion can only be detected by radiography examination or ultrasonic examination.

Causes :

- When cleaning slag in the inter pass is not clean.

- Welding slag melt first in front of a welding arc.

- Slag weld trapped in the weld pool.

Remedies :

- Make sure every inter-run is clean.

- To prevent slag inclusion, make sure the electrode angle is correct.

3. Undercut Welding Defect.

The undercut is one of the classics, along with slag inclusion and porosity, which occur most in welding. It primarily happens because a bad maneuver is done by the welder and the arc melts the side of the pool without properly filling it.

While it looks minuscule, the undercut could be one of the sources of the initial crack that later on will propagate and break the material. To avoid this, try to avoid using an overly high welding parameter while moving along the weld bead evenly to avoid traveling too fast. Undercuts are usually surface defects, and thus can easily be recognized visually. Liquid penetrant and magnetic particle examination can also help to detect it.

Causes Undercut Welding Defect :

- The welder is not competent when he weaving the electrode.

- The electrode angle is not correct.

- Welding Current is too high.

- Incorrect in selecting shielding gas when using the MAG process.

Prevention :

- You must reduce the welding current.

- Use multi-run welding techniques in the flat position.

- Reduce your weaving width or you can change to use multi runs welding.

- When you use the MAG welding process, you can mix gas composition in accordance with material thickness.

4. Cracks.

While there are many causes on which a crack can occur, the crack can also occur during welding, making it worth mentioning. Crack is highly dangerous because it will greatly reduce the material’s strength and will propagate along the way when the material is loaded.

Therefore a complete repair procedure should be done at once when the crack is detected by any examination method (radiography, liquid penetrant, and magnetic particle). Some cracks can happen during a non-welding process such as lamellar tearing. While cracks like hot and cold cracks happen mostly because of welding.

Hot Cracks and Cold Cracks.

In hot cracks, cracks happen because of pre-existing contaminants like; sulfur and phosphorus inside the base metal. Those contaminants form a carbide that has a lower melting temperature than the base metal itself. When the heat from welding highly increases the temperature, those carbides will melt and decrease the material’s strength.

Combined with the stress applied to the material, it will break and propagate fast without even waiting for the material to cool down. Hence the name hot crack. Ordering a killed material can greatly reduce the chance of a hot crack to happen, or simply regulating the inter-pass temperature can also work.

A different thing happens in the cold crack, high hydrogen concentration around the weld metal is the primary cause. When the weld metal is hot, the hydrogen in the environment might enter the metal by means of diffusion. This hydrogen atom will mostly reside in the HAZ (Heat-Affected Zone) where the crystalline is most susceptible due to its coarseness.

The existence of hydrogen will turn the material into its brittle state which continuously builds internal stress up until its breaking point. This process takes so much time that its breaking point will happen even when everything is already cooled down. Hence the name cold crack. To avoid this, using a low-hydrogen electrode will greatly help, and also doing PWHT (Post Weld Heat Treatment) can reduce the residual stress and also allow the hydrogen to escape.

5. Tungsten Inclusion.

This type of defect occurs only on welding GTAW. Defects occur due to the melting of tungsten into the weld metal. This defect will be known if we use radiography testing, the defect looks like a light area.

Causes of Tungsten Inclusion :

- The Tungsten electrode is in contact with the weld pool during the welding process.

- The hot tungsten electrode is in contact with filler metal.

- Occur a crack in the tungsten electrode.

- The use of welding current exceeds the maximum temperature limit of tungsten electrodes.

Remedies :

- Keep the electrode tip distance from the weld pool.

- Make sure the electrode condition is good for use or nothing cracks.

- Use the welding current according to the maximum electrode temperature.

- Don’t let the hot electrode come into contact with the filler metal

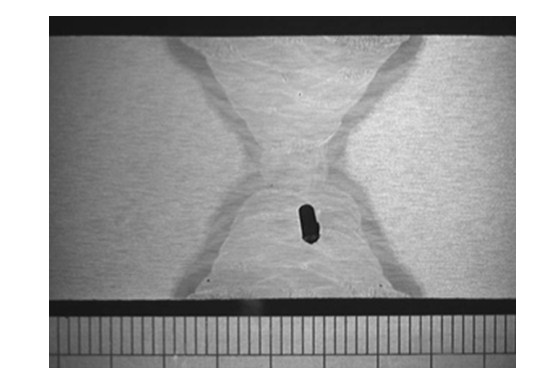

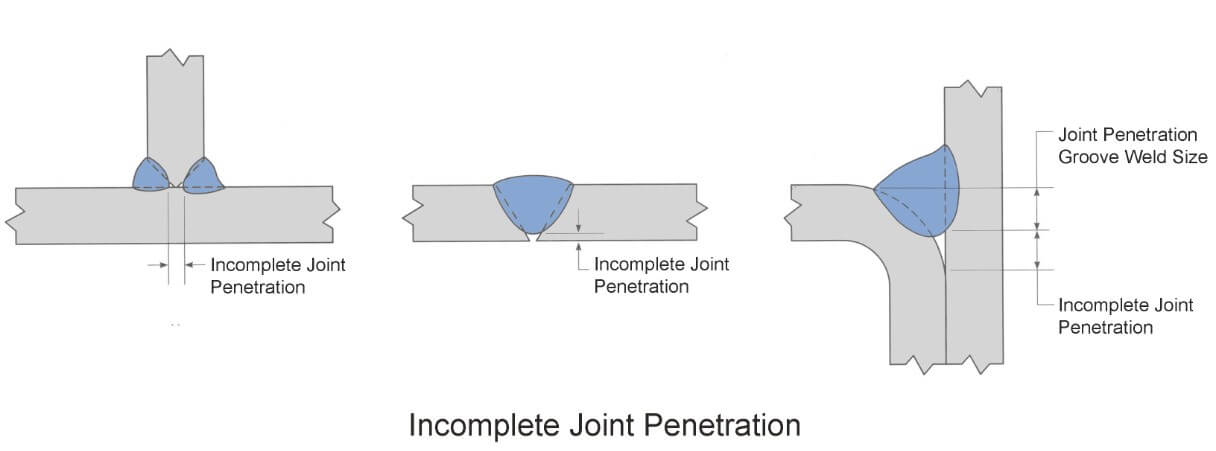

6. Incomplete Penetration.

Welding defects occur in the root area of the weld.

Causes :

- The less welding current.

- The wrong electrode position.

- The electrode movement is too fast, and also the diameter of the electrode is too large.

Preventive :

- You must increase the welding current suitable for the welding procedure.

- Use the correct diameter electrode suitable for material thickness.

7. Over Spatter.

Spatters can be removed by being ground or struck using a hammer. Cause of this defect is because the current is too large and also the welding arc is too high.

Causes :

- The welding current is too high.

- The arc distance between the electrode and the workpiece is too long.

- Moist flux electrode.

- Gas shielding in the GMAW process 100 CO2.

Preventive :

- Use the correct welding current (see in WPS).

- You must reduce the arc length.

- Before use, the electrode must be dried in the oven.

- Mixing gas shielding CO2 with Ar.

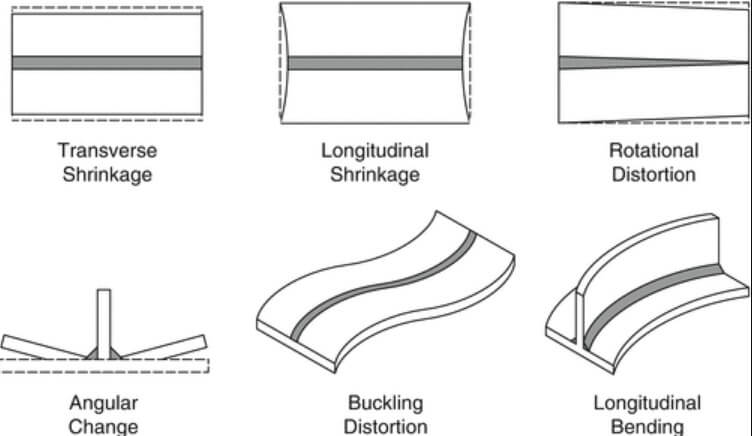

8. Distortion.

Distortion is caused by excessive heat input causing the material to undergo a change in angle.

Causes Distortion :

- Incorrect welding preparation, start from incorrect tack weld.

- Incorrect welding sequence.

Remedies Distortion :

- Before welding, make sure that the material to be connected is straight and the tack weld is strong.

- You must have a qualified welding sequence.

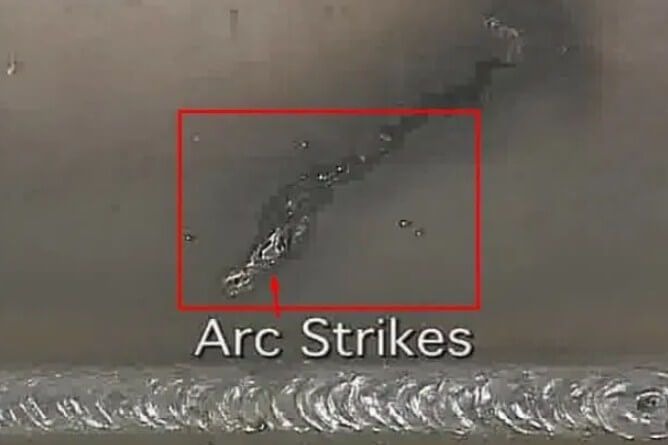

9. Arc Strike.

Arc Strike is a type of welding defect occurring in the material and adjacent to the weld metal. Because welders accidentally touch the electrode to the workpiece area causing the arc strike.

Causes of Arc Strike welding defects:

- Access to the welding groove is difficult.

- The coating of the electrode holder is peeling.

- Wrong laying electrode Holder.

- The clamp at the base metal is not good.

Prevention :

- Access to welding should be easier.

- Periodically check the electrode holder.

- Provides a place to put the electrode holder.

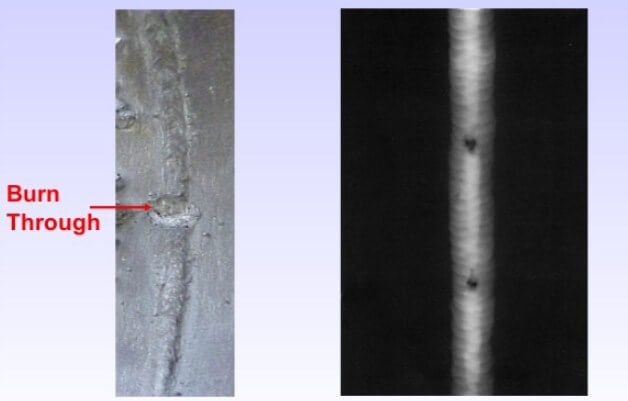

10. Burn Through.

This occurs at the weld root, this form of welding defect is a hole.

Causes of Burn Through :

- Welding current that is too large.

- The root face and root gap are too large.

- The welder is not competent.

Remedies :

- Look at the Welding Procedure to setting the correct welding current.

- Welding travel speed must be increased.

- Welding preparation should be correct, you can look at the welding procedure to set the correct size of the root gap and root face

- Welders must be trained.

See: Definition Of Welding and The History

Conclusion

After we learn that there are just too many variables that may cause a discontinuity. It’s just impossible to avoid each and every one of them, so making mistakes every now and then is pretty normal as long as we know how to deal with it.

However, it doesn’t mean that we have to take things for granted. We can surely do our best to avoid making mistakes so frequently if we strive. That’s what we should do to fight the entropic force of nature, by striving for excellence.