Welding tools are a set of tools specifically designed to support the work of a metal construction professional or someone just starting a business in this industry. This instrument serves to help weld workers to unite metal materials in a certain way to form a single object. Without this instrument, it would be impossible for a professional welder to make cuts in tough material with accurate measurements.

The main reason why tools for welding must be owned by every welder is that the welding process has a complex set of procedures. For example, before entering the welding procedure, the metal preparation process itself already involves a lot of equipment, including measuring, cutting, and cleaning.

Talking about tools for welding, maybe focus on the welding machine as the main instrument. However, this profession requires quite a lot of basic equipment. There are various choices of best welding tools that are marketed under various brands and types to provide the best welding equipment according to what a welder needs.

Table of Contents :

Welding Tools List :

As a beginner, you may be a little unfamiliar with welding tools names and pictures which are divided into several categories. Such as safety equipment from welding helmets, masks, gloves, and several other accessories.

Then the most common measuring tools such as a tape measure and a metal scribe, and a gauge that is mandatory. If you need detailed information regarding all the essential tools required in any welding project, here is a list of welding tools for beginners that should be noted.

1. Auto-Darkening Welding Helmet.

A welding helmet is a part of welding safety equipment that serves to protect the face from sparks and welding hot temperatures. The helmet glass section has 3 layers, namely clear-black-clear which functions to protect the eyes from visible and ultraviolet radiation when welding.

Each helmet glass has a code number, namely 6, 7, 8, 9, 10, 11, 12, and 14.

The greater the number value, the higher the density or darkness of the glass. The goal is to adjust the condition of the welder’s eyes by maintaining a light color after opening the helmet glass. Because the greater the amperage, the brighter the light produced. Without an auto-darkening welding helmet, it will be difficult for the welder to see clearly during the welding process.

2. Jacket Or a Welding Apron.

Protection of the whole body from hot temperatures and welding sparks using a welding jacket is important. Because this safety equipment is made using natural fibers that are heat resistant so that it will not make clothes burn easily. Another option for the welder is to use a leather welding apron as additional protection because ordinary materials are unable to minimize the heat temperature.

3. Welding Shoes.

There are many types of shoes on the market that are specifically designed to make the welder safe from welding sparks, heat, flames, and hot molten metal. Usually, shoes are made of leather and the front of the shoe has a steel plate that serves to protect the feet from heavy objects and sharp objects that fall. Besides, the insulating properties of these shoes also protect from the dangers of electric shock.

4. Welding Gloves.

Welding gloves are very important to use as protection against hands from sparks and heat due to the welding process. Pay attention to the size of the gloves used, where a good glove will provide a more flexible and flexible range of motion. It is also important to pay attention to the condition of dry and damp hands before using gloves so that welding gloves can work optimally.

Good welding gloves are recommended to be 16 cm to 18 cm long so that they can protect the welder’s hands as a whole and can minimize the feeling of heat. The materials used cannot be chosen randomly, such as plastic, rubber, and cotton because these three materials are not able to reduce heat flow. Recommended material of leather which will not transmit the heat.

5. Safety Glasses.

Safety glasses have several functions to reduce the risk of cataracts, nearsightedness or nearness, and blindness as a consequence of work that involves the eye seeing something sharp. The shape of the welding goggles resembles swimming goggles with specially designed lenses with varying degrees of shade. Because these glasses function as eye protection from the flashes of light resulting from the welding process.

If the shade size is higher, it means the darker the color of the glasses. Welding goggles of a high shade are also recommended for electric or arc welding welders. Because the level of light in electric welding tends to be very sharp and bright. Even now there is a type of auto-darkening, where the glasses automatically adjust to the level of light in front of the eye.

6. Ear Plugs.

The welding process produces a lot of noise which requires the welder to be exposed to noise during working time. So using earmuffs or earplugs is very appropriate when the welder is exposed to 40 to 50 dB of sound and 100–8000Hz. Earplugs are generally designed with large enough pads and cover the entire earlobe. Even so, using ear muffs for too long is also not recommended because it is feared that they will shrink and harden the pads.

7. A Mask or a Respirator.

Masks or respirators serve to provide fresh air to be inhaled by the respiratory system. Because welding produces a lot of fumes which can be dangerous for the welder if inhaling large amounts of these fumes. For example, room welding has a bad air circulation system due to the combustion or melting process of the material. The smoke produced is like clean powder which is harmful to the respiratory system.

8. Measuring.

The success of the project apart from the professionalism of the welder, also greatly depends on making measurements before the welding stage. The measurement process is like an investment that is very important for the success of the final project. A welder in measuring and marking devices will need a measuring tape, calipers, metal T-square, and some sort of marking tool for perfect results.

9. Welding Clamps.

Welding clamps is a tool that functions as a clamp or clamp so that the welding field will not change shape, position, or size which could complicate the work. These clamps are available in various sizes, and a welder has at least 10 clamps to support the project being done.

10. Welding Magnets.

Welding magnets are magnets with a very strong magnetic field as an important tool in the welding process. It can attach to any metal surface and can hold objects at angles of 45, 90, and 135 degrees in various sizes to suit the needs of the project. Alnico, neodymium, or samarium cobalt materials in magnets can ensure the fast setting and a containment strong enough to meet the demands of a safer welding process.

11. Welding Gauge.

Welding gauge is the main equipment that must be owned and mastered properly. Its function is to determine the dimensions of welding preparation such as bevel angle, width, and gap. Besides, it is also used to measure the dimensions of the welding results such as capping height, root penetration height, measure the fillet weld, and the depth of the undercut defects. Because this tool is used in visual inspection activities, a welder must understand exactly how to operate it.

12. Electrode.

The electrode is a tip attached to the end of the tool through which an electric current is passed from the welder to the material. For different applications, you need different types of electrodes that are applied according to your needs. Welding with rod electrodes offers many advantages over the MIG / MAG and TIG Welding processes.

In principle, almost any material can use electrode welding. This process is mainly used in steel and pipe construction but is also used in the metal trade and industry. Besides, the welder can easily work outside as it is independent of the shielding gas. It even allows for electrode welding in unfavorable weather conditions such as wind or rain.

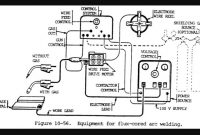

13. Wire and Electrode Feed.

Each welder has different preferences and expertise in the various uses of various welding methods. For a beginner welder, the wire and electrode feed is the easiest type to apply. This process uses a protective gas so that the weld metal is protected from contamination from the external environment. Also, wire and electrode feed machines are specially designed for light welding like FCAW Welding.

Wire feed welding works by inserting wire electrodes into a machine that displays the electrodes in the shape of a gun. After the welder presses the trigger, the power supply goes into action and the rollers start and the arc comes to life.

The arc which continues to heat the metal simultaneously melts the electrodes of the wire. The two metals are melted together to form a weld joint. During the welding process, the shield gas protects the metal from environmental contamination.

14. Angle Grinder.

An angle grinder is an electric-powered tool that can be used for a variety of metal fabrication jobs including cutting, milling, deburring, finishing, and polishing. Choosing the right disk can replace many tools and make the most complex of intensive jobs done faster and easier. On the other hand, the device is easy for beginners to control by always ensuring safety with the right precautions.

15. Metal Brush.

Metal brushes are versatile welding tools that are effective at removing contaminants created during the welding process. For example, the surface layer is covered by a lot of slags that are left after the weld is finished.

Well, the welder must use a metal brush to scrape the slag layer so that the final project result is visible. There are many types and styles of metal brushes with different functions and ways of application.

16. Hammers.

Welding hammers used to clean the welding surface from spatter or slag. You can use a chipping welding hammer as an alternative if there is not a grinder.

See: Welding Symbols Chart to Learn

If you have experience in welding, this opportunity can be used to generate income with a small business. Make sure that all the required welding tools are in place. Even if not, now both second-hand and new welding tools for sale are easy to find.

From the welding list already mentioned, surely you have an idea of what tools are needed to make any type of project run smoothly. Finding the best quality welding tools is indeed a hassle. Whatever trademark is chosen, all will affect the quality of the work.