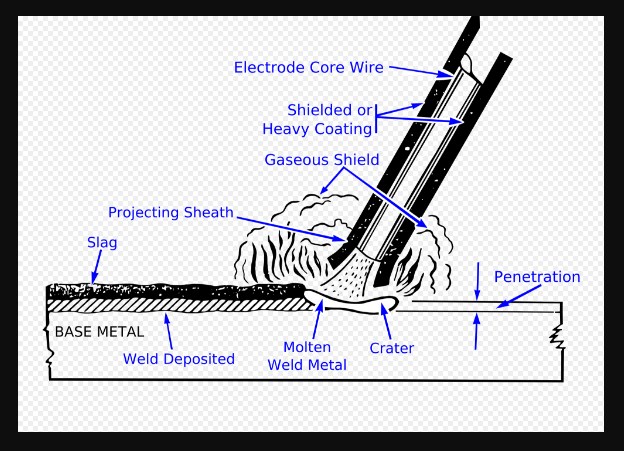

SMAW (shielded metal arc welding) is a welding process in which the source of heat coming from the electrical current. This heat is the result of the conversion of electric power that is converted into heat when the electrode is attached to the base metal. The meeting between the electrode and the base metal will cause ion exchange.

The Shielded Metal Arc Welding process has three types of polarity, the first is Alternating Current (AC), Direct Current Reverse Polarity (DCRP), and Direct Current Straight Polarity (DCSP). For machine type, SMAW has three kinds of current that are machine direct current (DC), the machine with alternating current (AC), machines with a combination of direct current (DC), and alternating current (AC). You can look at processing melt the electrode in this picture.

Table of Contents :

Shielded metal arc welding machine parts and procedure:

SMAW machine parts:

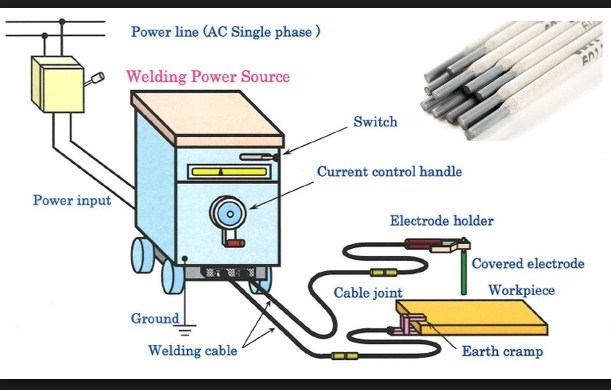

- Machine

Shielded Metal Arc Welding machine is the main part of this process, because without machine certainly, we can not do welding process. - Electrode Cable

The function Electrode cable connects the current from the welding machine to the electrode which we use to weld the base metal. - Massa Cable

Has a function for connecting current from machine to base metal, after that base metal and electrode touch then will welding process is happening. - Welding Power Source

Have to function for supply current from electrical source to welding machine. - Current Control

For control current output which uses for the welding process, big or little the current dependent form type or thickness of material (base metal). - Electrode Holder

To hold the electrode so we can do the welding process easily. Otherside holder too has a function for an electric current to the electrodes. - Earth Cramp

To connect the machine to the base metal. - Switch

For on or off the welding machine. - Electrode

As a filler metal, after the welding process finish then the electrode will change be weld metal. The electrode has a flux which function is to protect steel melting when the welding process takes place.

SMAW Welding can use for anything weld joint or welding position. Otherside we use this process for underwater welding, but the tools must be complete again suitable for underwater welding procedures. If we do not follow the procedure then can cause an accident, for example, electric shock or other accident types.

See: TIG Welding Machine

Advantages and Disadvantages SMAW Welding:

SMAW has advantages and disadvantages, this the explain.

Advantages Shielded Metal Arc Welding:

- Can use to welding for all type joint.

- SMAW can use all welding positions.

- We do not need gas for shielding the molten weld metal.

- Do not need much preparation before welding.

Disadvantages Shielded Metal Arc Welding:

- We must clean the slag after the welding process is done.

- There are spatters.

- One electrode just can produce weld metal around ten to fifteen centimeters.

- The speed can not fast because we must change the electrode.

An explanation of what is Shielded Metal Arc Welding and process the above we can from a variety of sources, if you want to add captions please provide them in the comments field or existing contacts on this page.